Add to Cart

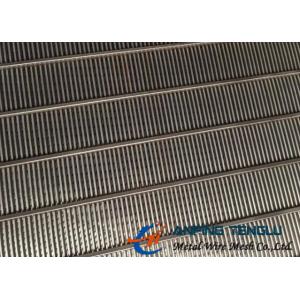

Wedge Wire Screen Tube

Wedge wire screen tube, also called round slot tube. It is made of stainless steel wire, which is the most popular type because of outstanding chemical stability and corrosion resistance. The wedge wire screen tube is composed of working profile and support profile. It is produced on an automotive machine. The support profiles is placed on the suit position of the machine, during the surface profiles are spirally wounding, the support profiles are welded onto the surface profiles.

Normal type wedge wire tube has continuous and regular angles on the edge. It is economical, which is suit the applications where the accuracy is not very strict. Perfect round wedge wore tube is produced by the strict standard, which has better filtering accuracy than the common type. Additional, the perfect round type can be used in the most precise machines and complete the arduous filtering task.

| Tube Diameter | 25 mm-1500mm |

| Tube length | 0.3m-12 m. |

| Slot Size | 0.05mm-2.5mm |

| Surface Profile Type | Triangle Wire |

| Support Profile | Triangle Wire, Round Wire, Flat Bar or Wedge Wire |

Materials: stainless steel 304, 304L, 316, 316L, etc.

Features:

Accurate filtering performance.

High efficiency.

Narrow slot openings.

Normal or high grade type for choice.

Various edge types.

Wide range of diameters for choice.

Special sizes can be customized.

Economical but high grade.

Corrosion resistance.

Rust resistance.

Long service life and durable.

Applications:

1) Petroleum industry. Oil filtration.

2) Water treatment industry. Desalination of seawater, treatment of industrial water and domestic water. Water softening treatment.

3) Chemical industry. End products of chemical organic solution filtration, such as acid, alkali liquid filtration, alcohol and other products filtering.

4) Hydro-geological exploration.

5) Drilling construction.

6) Geothermal development.

Wedge Wire Tube Specifications:

| Slot Size(S) (mm) | Profile Wire (mm) | Support Rod (mm) | |||

| Triangle Wire A1×H1 | Triangle Wire A2×H2 | Round Rod | Flat Bar | Wedge Wire | |

| 0.05 | 0.5×1, 1×2 | - | - | - | |

| 0.1 | |||||

| 0.15 | |||||

| 0.2 | 2, 3, 4, 5, 6, 7, 8 | ||||

| 0.25 | |||||

| 0.3 | 1.5×4, 2.2×3.5, 2.2×4.5, 2.8×5, 2.2×3.5, 2.2×4.5, 2.8×5, 3.1×6, 2.8×6.5, 3.4×7.5 | ||||

| 0.4 | |||||

| 0.5 | 2×25, 3×25, 4×25 | 3×5, 4×6, 4×7.5 | |||

| 0.6 | |||||

| 0.7 | |||||

| 0.8-10 | 1.5×4, 1.8×3, 2.2×3.5, 2.2×4.5, 2.2×5, 2.3×3.8, 2.6×4.3, 2.7×4.2, 2.8×5, 2.8×6.5, 2.8×8, 2.8×10, 2.9×4.7, 3.1×6, 3.2×5.5, 3.4×7.5, 3.5×5.7, 5×7, 5×10, 6.9×9.4, 8.5×11.5 | ||||

| Tube Diameter: 25mm, 28 mm, 32mm, 38mm, 40mm, 42mm, 45mm, 48mm, 50mm, 53mm, 60mm, 65mm, 70mm, 76mm, 89mm, 100mm, 108 mm, 120mm, 133mm, 159mm, 196mm, 219mm, 240mm, 243mm, 273mm, 325mm, 400mm, 450mm, 500mm, 600mm, 700mm, 800mm, 900mm, 1000mm, 1100mm, 1200mm, 1300mm, 1400mm, 1500mm, etc. | |||||

Packing: Wedge wire screen tube will be packed firmly and securely. When packing, wedge wire screen tube appears in pipes. They are wrapped with moisture-proof paper or other packing materials inside. The outer package should be wooden pallets or wooden cases. Or we can pack goods according to your requirements.